Today is the official day that I finished making this tent. Actually, I finished it several weeks ago, but then there was the bag for the pole and also the sack for the tent itself. Those are done now, and after testing it in a storm, it’s officially done.

It started with my REI Half Dome tent, which I got in 2002 just before a backpacking trip to Sequoia National Park’s Rowell Meadows Loop. It worked well for a number of years. In 2008, on a kayaking trip, while pitching it on the banks of the Colorado River, a gust of wind caught the tent, snapping one of the poles. I temporarily fixed it by winding dental floss. Then, I had the other pole.

While sitting in a conference two years ago, I was thinking about designing a tent out of the remaining pole. That would eliminate the weight of the extra pole. Also, in Backpacker Magazine’s gear guide that had just come out, I saw an interesting design which used trekking poles as stays. My goal was to make it lightweight, under three pounds if possible. Single-wall designs are fraught with condensation problems, while double-wall tents have the added weight of the extra rainfly. I thought it would be good to combine them, making a two-door hybrid single/double-wall tent with a bathtub floor supported by a single pole, trekking poles to tension the front and back ends to allow for a free standing structure, and stake-down flies to provide ventilation and vestibule space. Also, I wanted to add catenary curves to all free edges to allow for a true taut pitch.

I made some initial drawings in conference with the aid of my laptop’s scientific calculator. Then, I plotted the shapes onto paper and made a 7% model. The geometry was off and things didn’t fit. Inspecting my work, I found that I had transposed some numbers mid-way, which carried the error to the rest of the calculations. I then decided to input everything from the beginning, and all calculations were made in a spreadsheet. The paper model from this worked out perfectly. Being apprehensive about sewing, I shelved the project for almost two years.

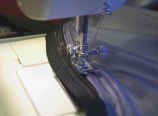

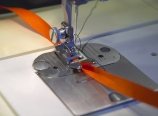

Before last Christmas, I decided to revisit the project. I ordered the fabric and miscellaneous parts. When they arrived, my sister taught me how to thread the sewing machine and went over some basic functions. I tried sewing a piece of fabric and mesh together. Then, I worked on a small segment of zipper, experimenting on making the ends and installing the slider. It was at this initial stage that I found out how painstaking sewing can be. But, it was too late to abandon the project.

The shapes of each piece was described as coordinates, in inches, and I transferred them onto the fabric and mesh using my tile floor as a giant graph paper. This worked well. There was a lot of mental manipulation to see how things fit and turned outside-in and inside-out. I think these were good exercises. I am pleased to say that there weren’t any major mess-ups. I also used parts from my old tent, such as pole hooks and grommets. Until near the very end, I had no idea whether or not everything even fit correctly. It wasn’t until about three weeks ago that I arrived at the stage where I could set it up preliminarily and see that it was going to work.

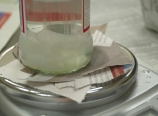

Then, there was the task of seam sealing, using clear silicone window caulking diluted with mineral spirits. I tested the tent under sprinklers for eight minutes, and it stayed dry. This was a relief. After that, I made a bag to hold the pole and stakes.

Last night, I set it outside, ready for the incoming storm. The forecast was for an entire night of rain with gusty winds up to 20 mph to last until this afternoon. After work today, the tent passed inspection.

Final weighing: 3 lbs 3 oz packed weight (tent, footprint, pole, stakes, sacks)

2-man, 3-season, hybride single/double wall tent with 2 doors and 2 vestibules

Freestanding with trekking pole stays and stake-down flies

28.1 sq ft floor area

9.3 + 9.3 sq ft vestibule areas

38 inches at peak height

Single footprint to cover areas under vestibules as well

Overall, I’m very happy with it. But in retrospect, I would have done some things differently—such as forgetting about the freestanding idea and just do stake-downs, incorporating catenary designs for all edges (thus, away with the bathtub floor), making bigger doors, using smaller zipper coils. Then again, had I known how much work would have gone into this, I might have never started.

You must be logged in to post a comment.